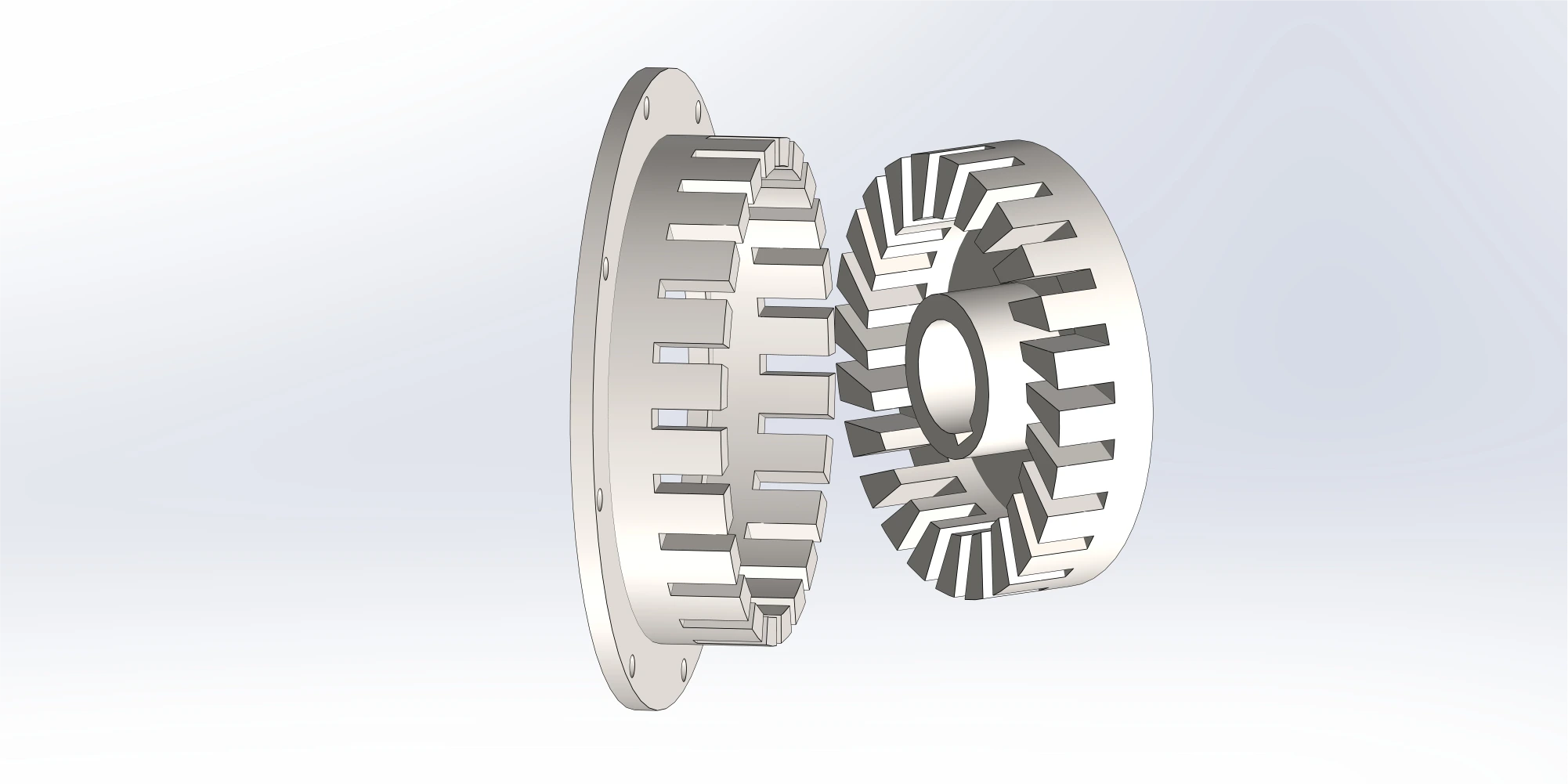

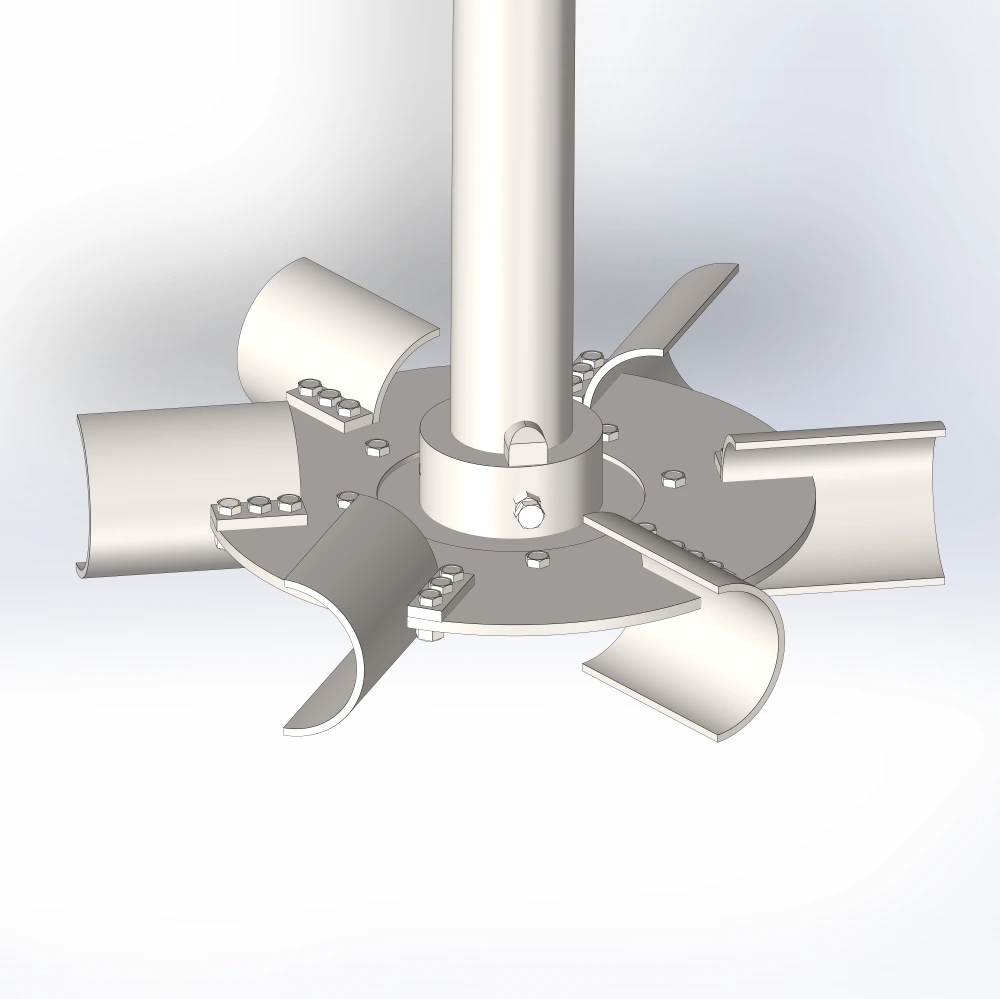

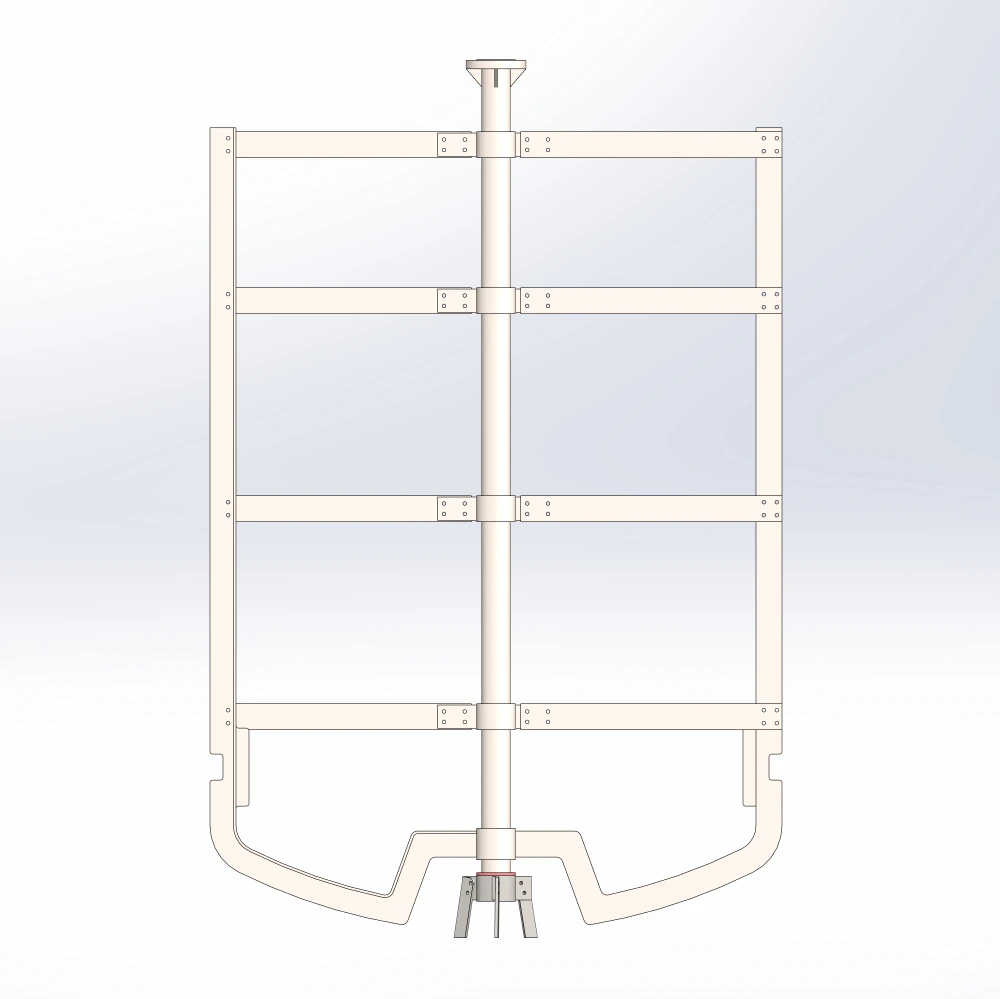

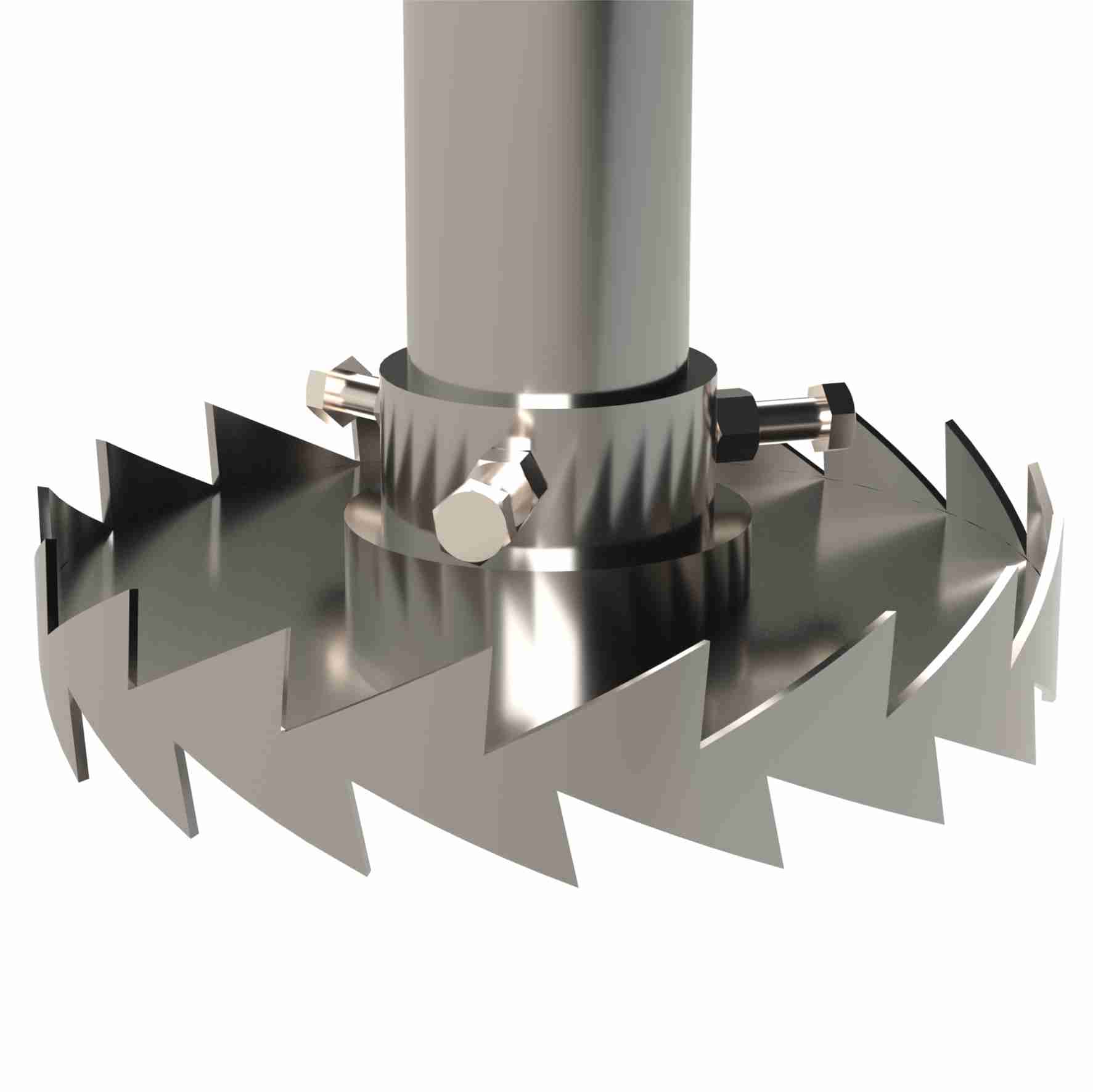

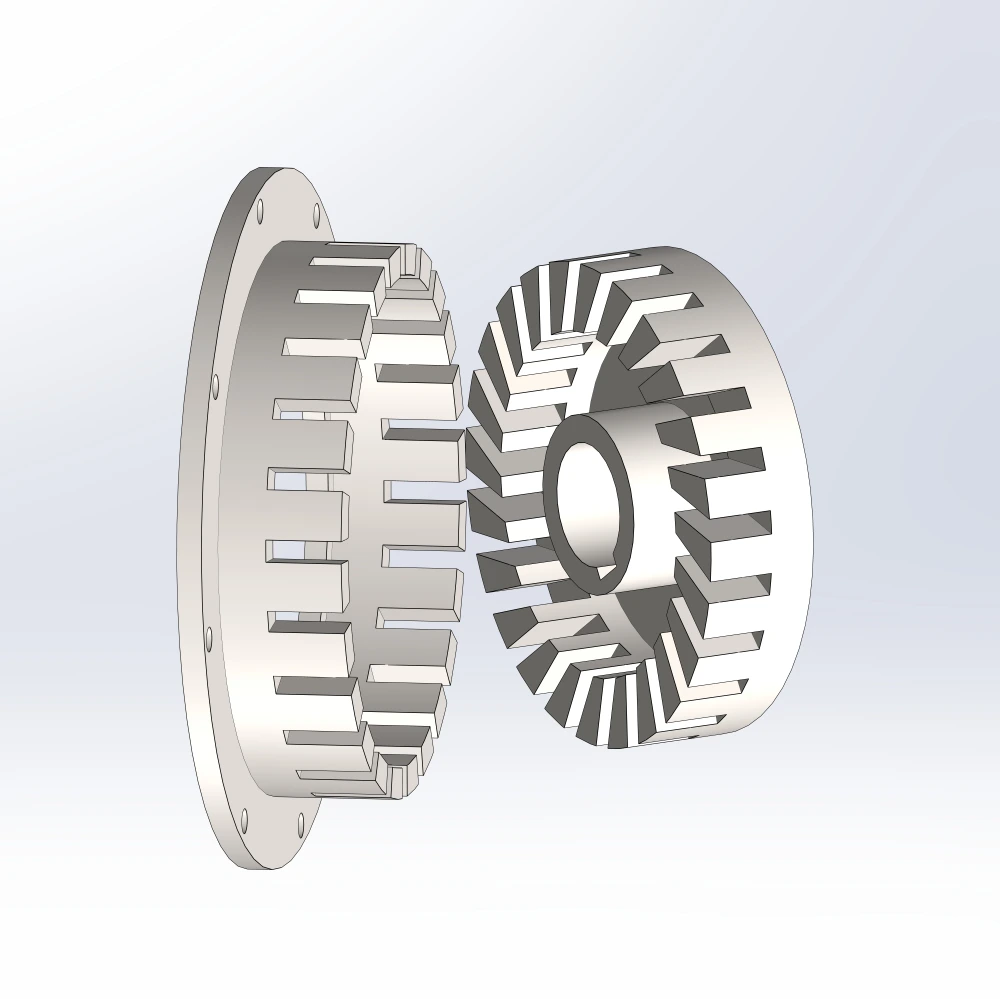

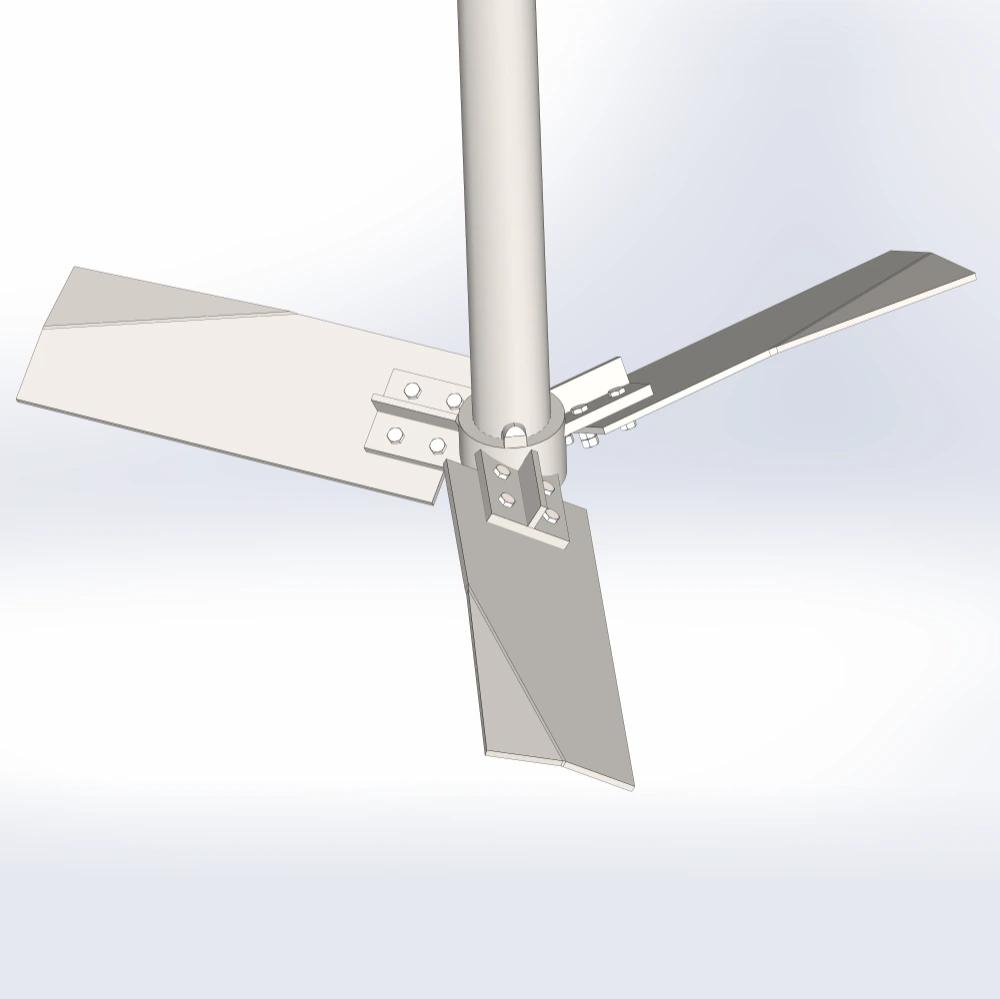

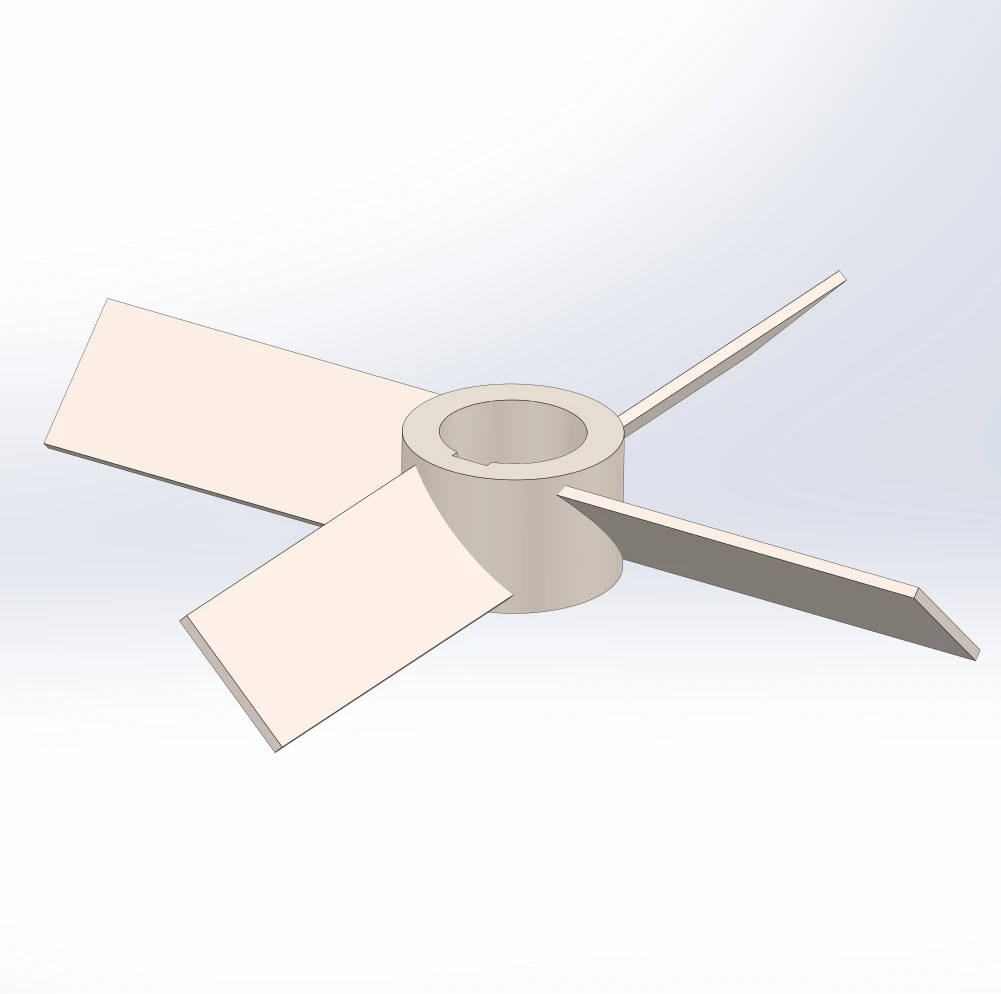

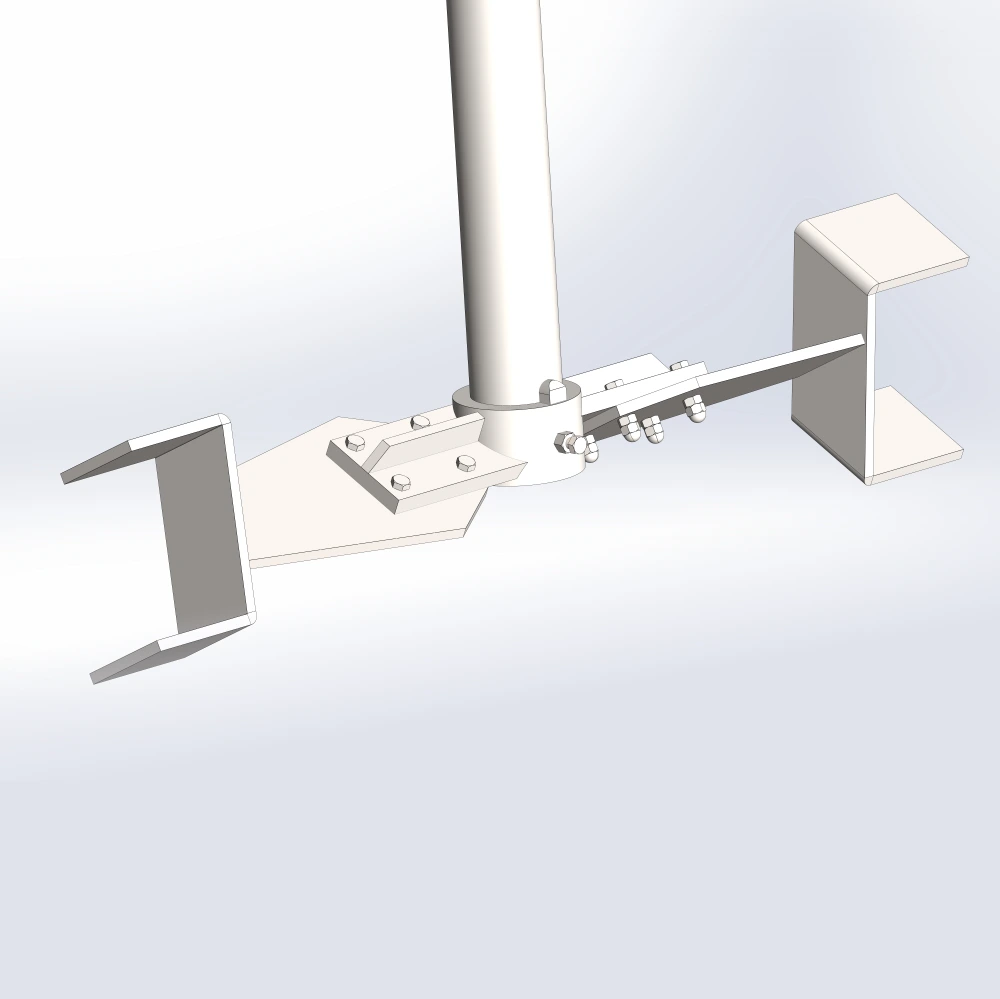

Stator Rotor Impellers are used in applications requiring extreme shear, typically in particle size reduction to the micron or submicron level. These impellers feature a rotating rotor and a stationary stator, which creates intense shear forces that break down particles. They are often employed in processes like emulsions, dispersions, and homogenization, where the precise size and uniformity of particles are critical. Stator-Rotor systems are particularly useful in applications such as pharmaceuticals, biotechnology, and fine chemicals where micron-sized particles are required for the final product.

Key Features of Stator Rotor Impeller:

- High-Shear Mixing: Produces intense shear forces for effective emulsification and dispersion.

- Precision Control: Ensures consistent particle size and uniform product quality.

- Efficient Processing: Ideal for reducing mixing times and enhancing process efficiency.

- Customizable: Available in various stator-rotor designs, sizes, and materials to meet specific requirements.

Applications of Stator Rotor Impeller:

- Chemical Industry: Emulsifying, dispersing, and reducing particle size in complex mixtures.

- Pharmaceuticals: Homogenizing active ingredients and ensuring consistent formulations.

- Food & Beverage: Producing fine emulsions and uniform mixtures in liquid products.

- Cosmetics: Creating smooth, consistent emulsions in creams and lotions.

- Petrochemicals: Enhancing dispersion and stability in oil-based systems.

Why Choose FEDA Inc. Stator Rotor Impellers?

At FEDA Inc., we design customized Stator Rotor Impellers engineered for maximum efficiency and durability. Our advanced designs ensure precise mixing, reduced processing time, and consistent product quality. For inquiries or custom solutions, contact us today!