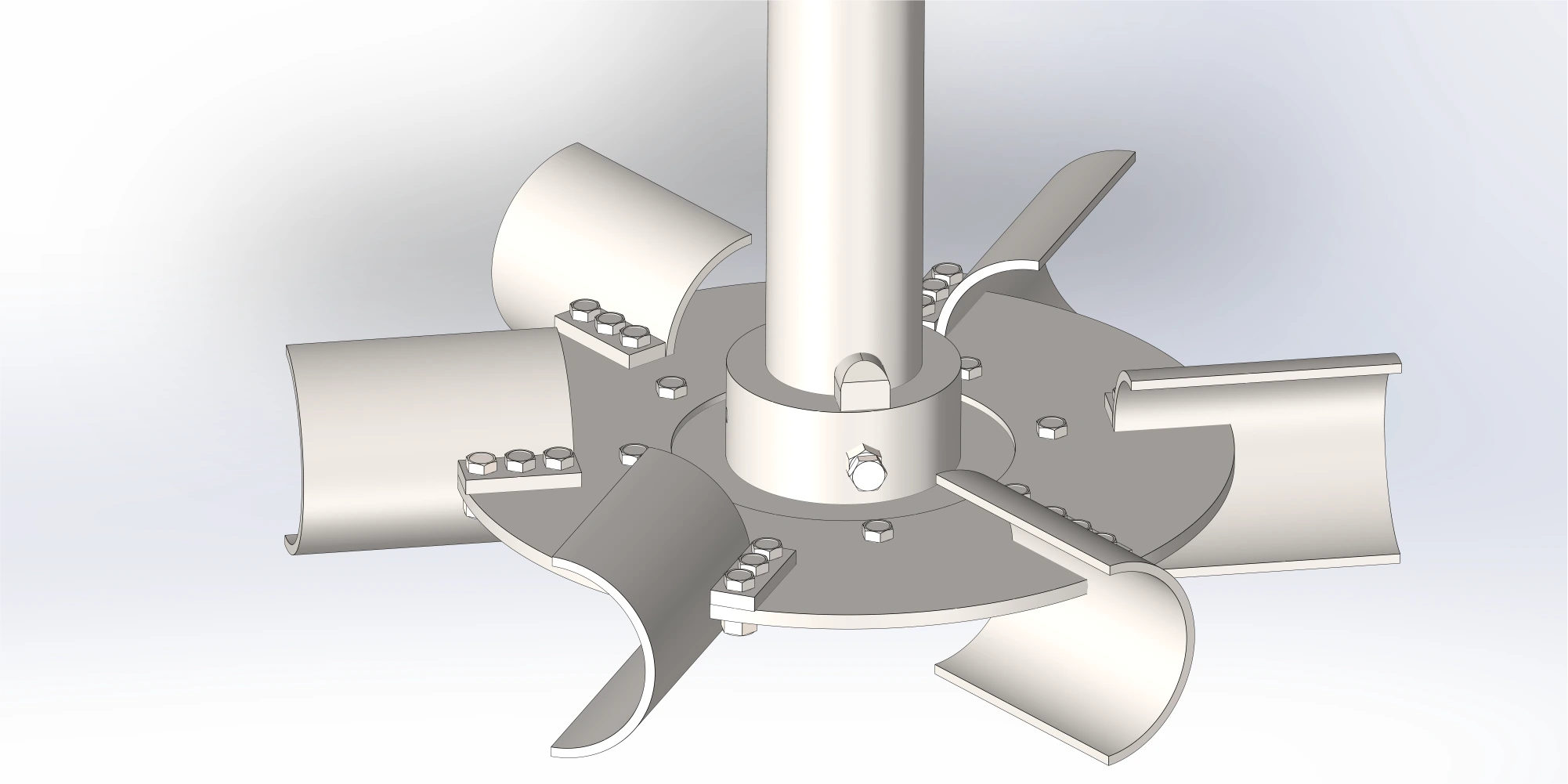

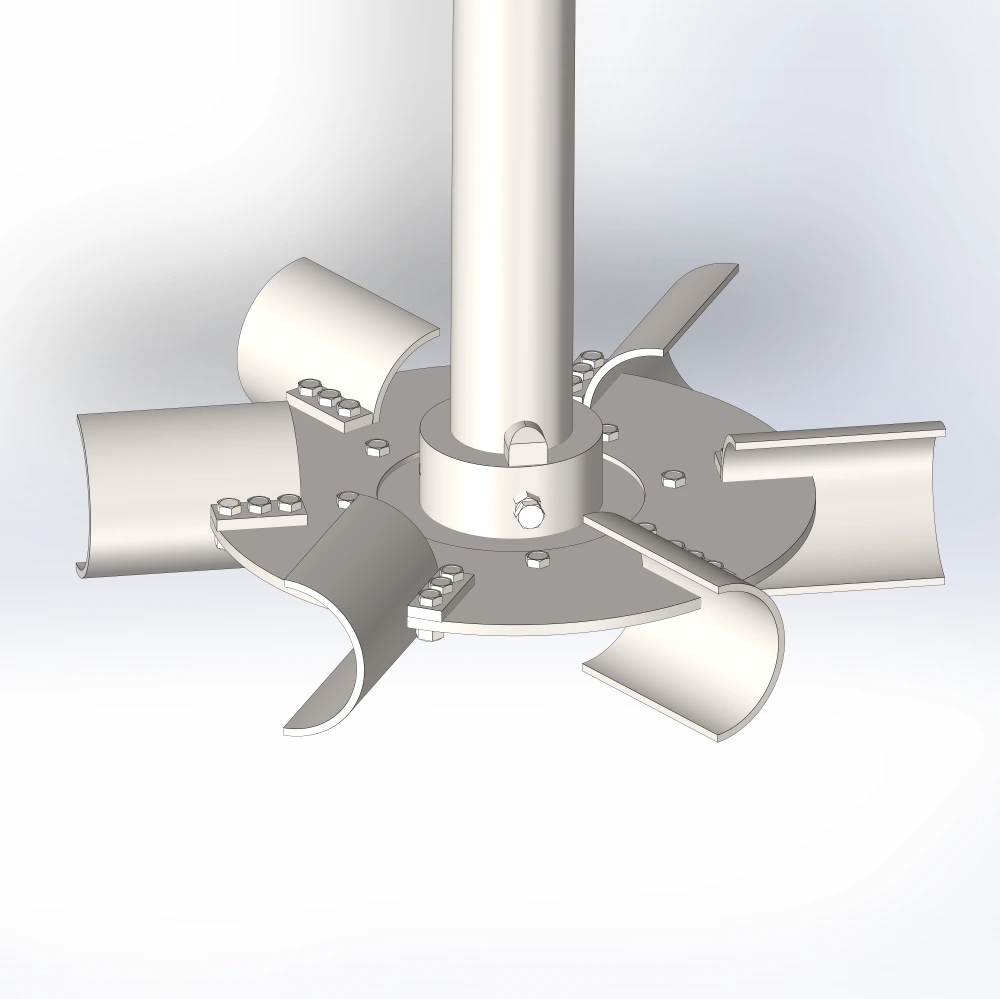

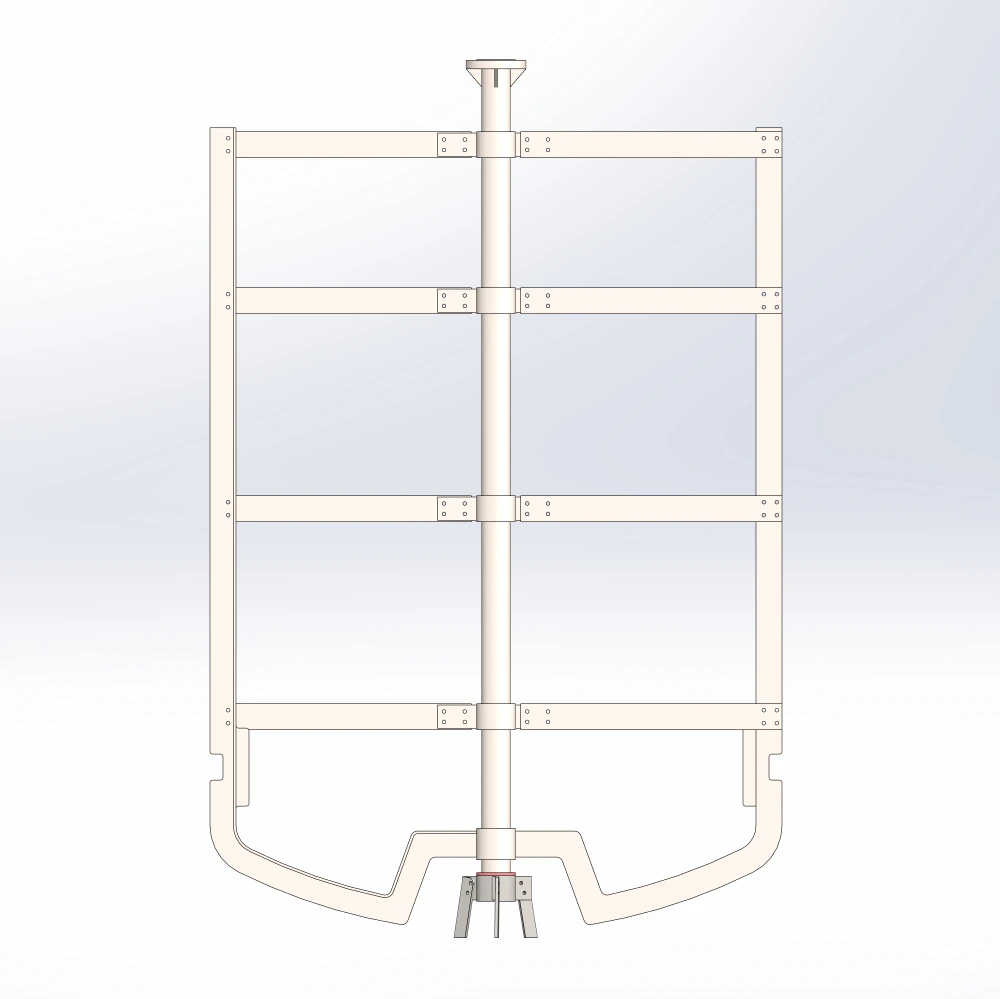

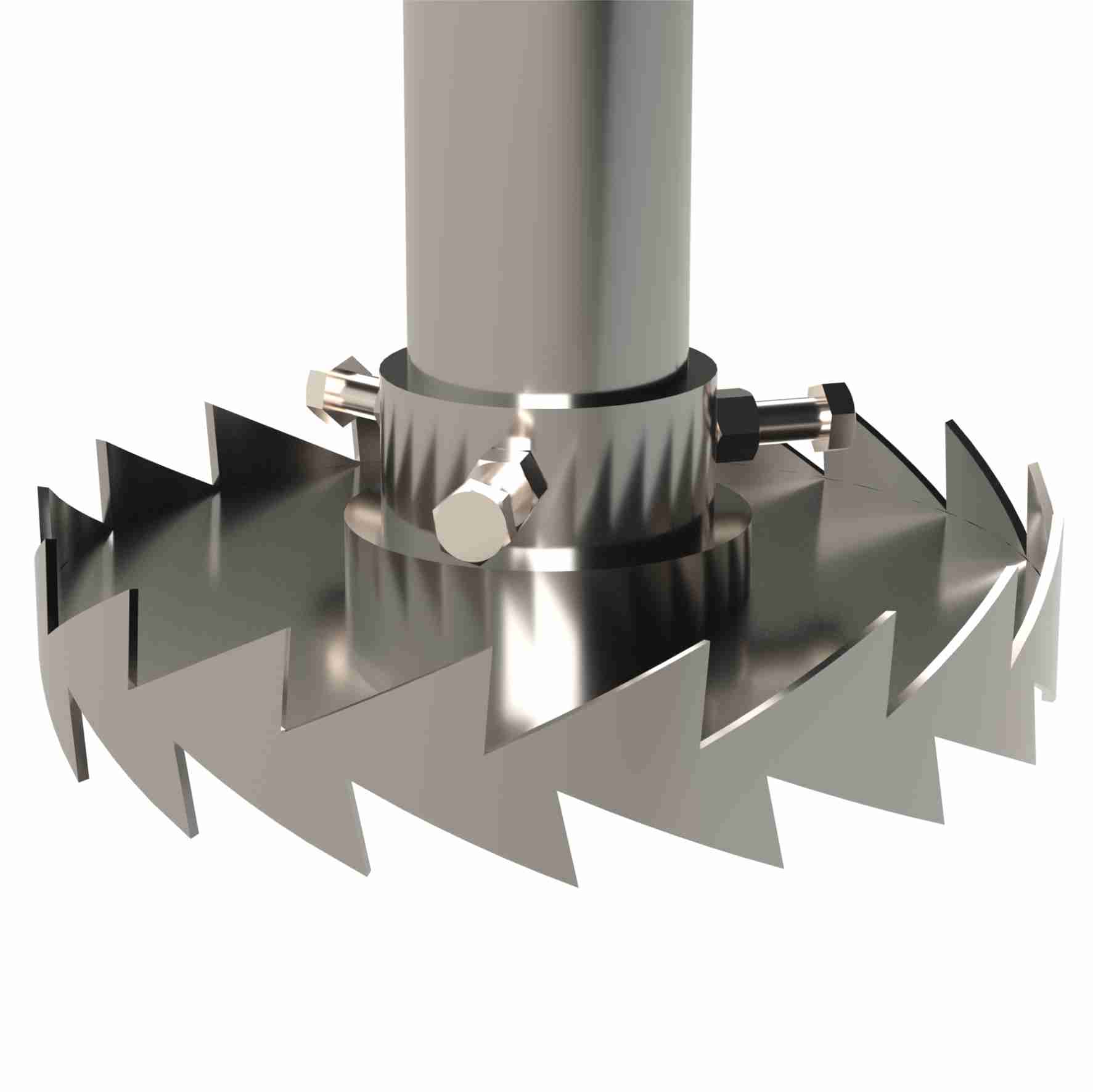

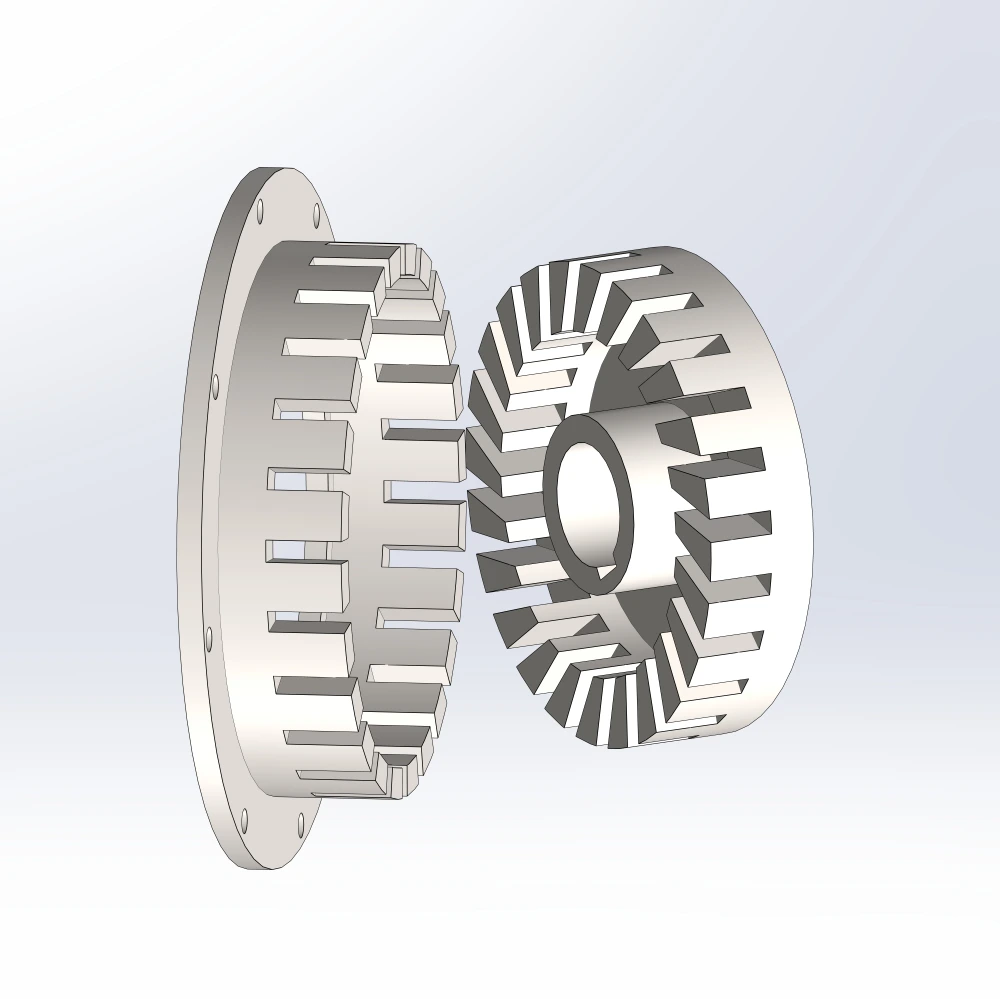

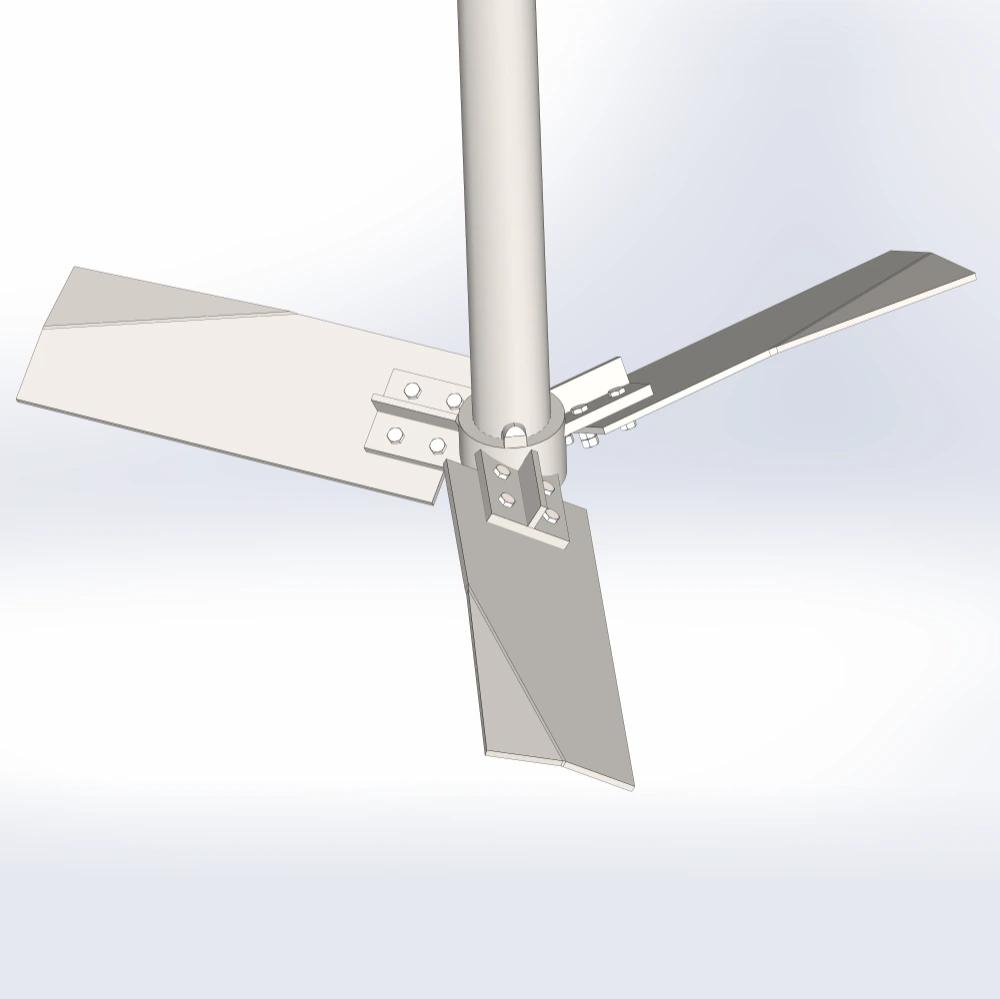

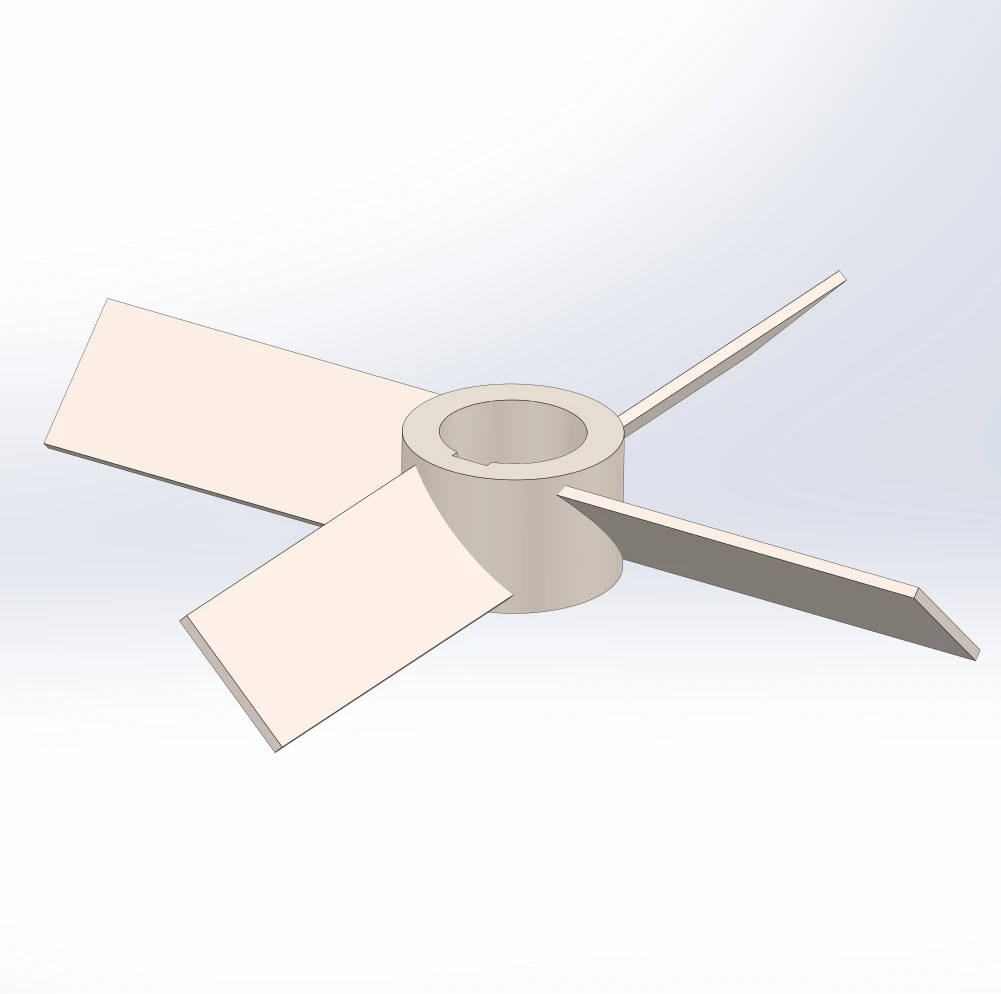

Curve-Disk Impellers are primarily designed for gas-liquid dispersion and gas absorption applications, such as in fermentation or oxidation processes. They feature a disk with a cowl or protective structure surrounding the impeller, which enhances the distribution of gas throughout the liquid. The Curve aids in minimizing the power consumption of the system by reducing vortex formation and ensuring a more uniform distribution of the gas phase. These impellers are ideal for processes involving high gas flow rates and are widely used in industries such as biotechnology, food processing, and chemical manufacturing.

Key Features of Curve-Disk Impeller:

- Optimized Flow: Curved blades ensure smooth, efficient fluid movement.

- Low Shear Mixing: Ideal for handling shear-sensitive products and delicate formulations.

- Energy Efficient: Reduces power consumption while maintaining effective mixing.

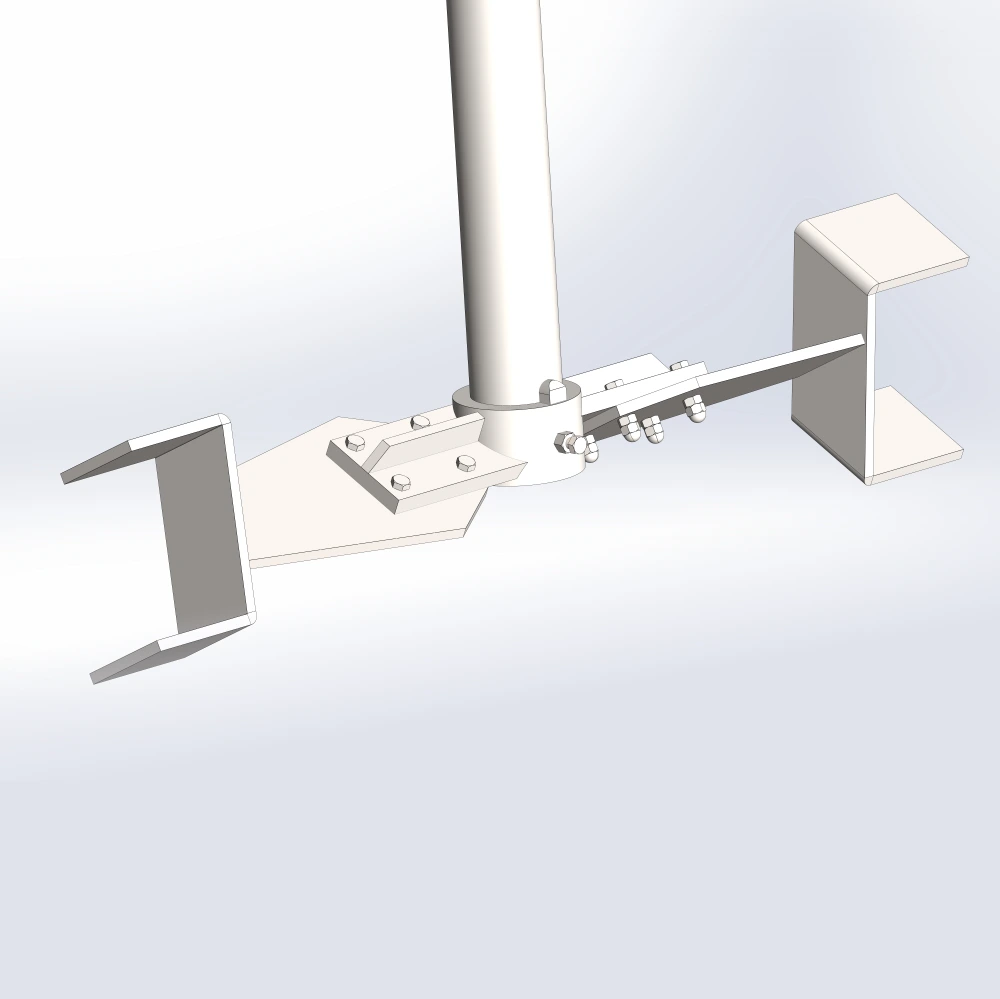

- Customizable: Available in different sizes, blade angles, and materials to meet specific process needs.

Applications of Curve-Disk Impeller:

- Chemical Industry: Uniform blending and heat transfer in sensitive processes.

- Pharmaceuticals: Gentle mixing of active ingredients and liquid suspensions.

- Water Treatment: Effective dispersion of additives and maintaining suspension.

- Food & Beverage: Consistent homogenization of liquids and delicate mixtures.

- Petrochemicals: Enhanced flow control in complex multiphase systems.

Why Choose FEDA Inc. Curve-Disk Impeller?

At FEDA Inc., we specialize in customized Curve-Disk Impellers engineered for precision and durability. Our designs are tailored to optimize your processes, delivering reliable and consistent performance. For inquiries or custom solutions, contact us today!