In dyestuff manufacturing, the mixing process is a critical factor that directly influences product quality, operational efficiency, and cost-effectiveness. Achieving the perfect blend requires advanced mixing technology to ensure uniform dispersion, precise particle size, and consistent dye properties. At FEDA Inc., we specialize in providing customized agitator solutions that address the unique challenges of dyestuff production, enhancing process reliability and performance.

Why Is the Right Mixing Process Essential in Dyestuff Manufacturing?

- Uniform Dispersion for Consistent Quality: Consistent dye quality depends on achieving a homogeneous mixture of raw materials. Our advanced agitators are designed to ensure thorough blending, reducing batch-to-batch variability and preventing issues like color inconsistency and sedimentation.

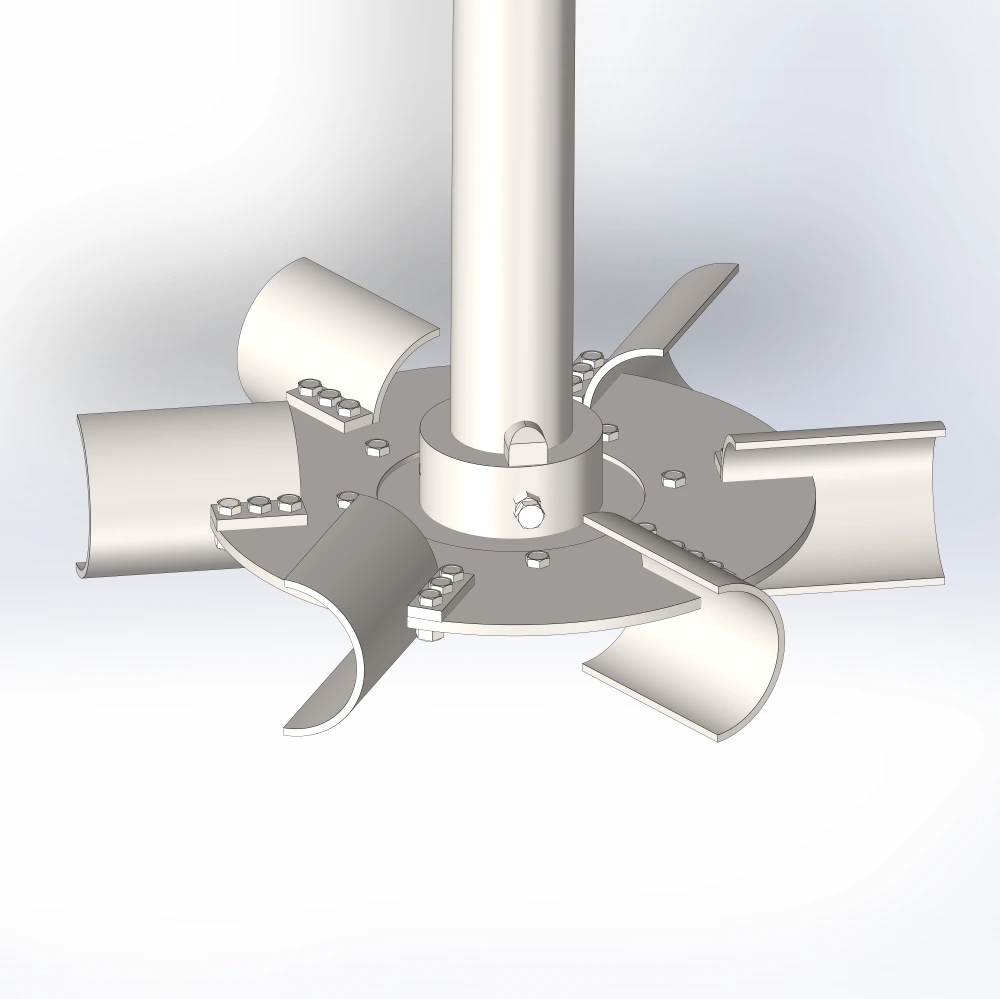

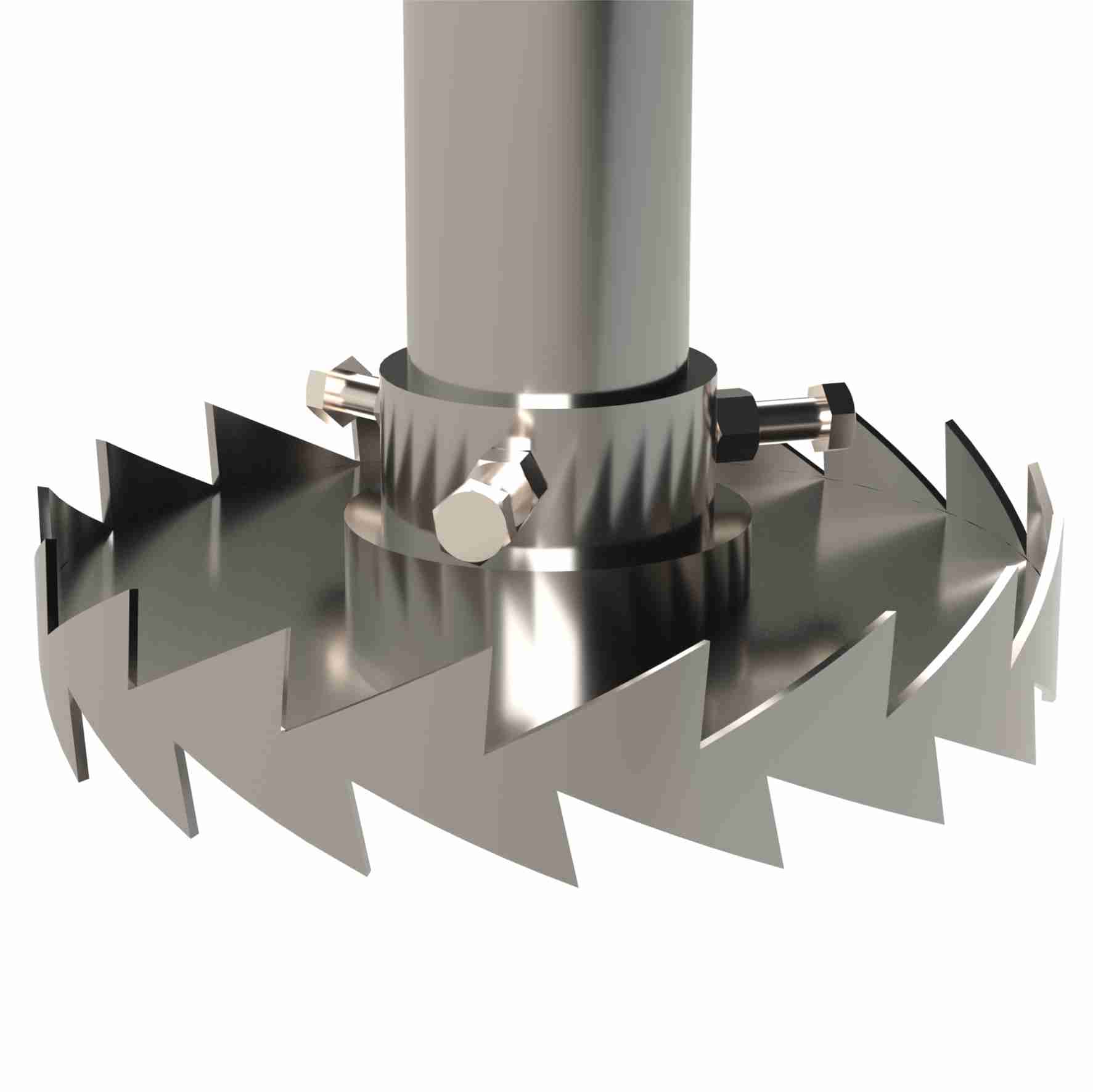

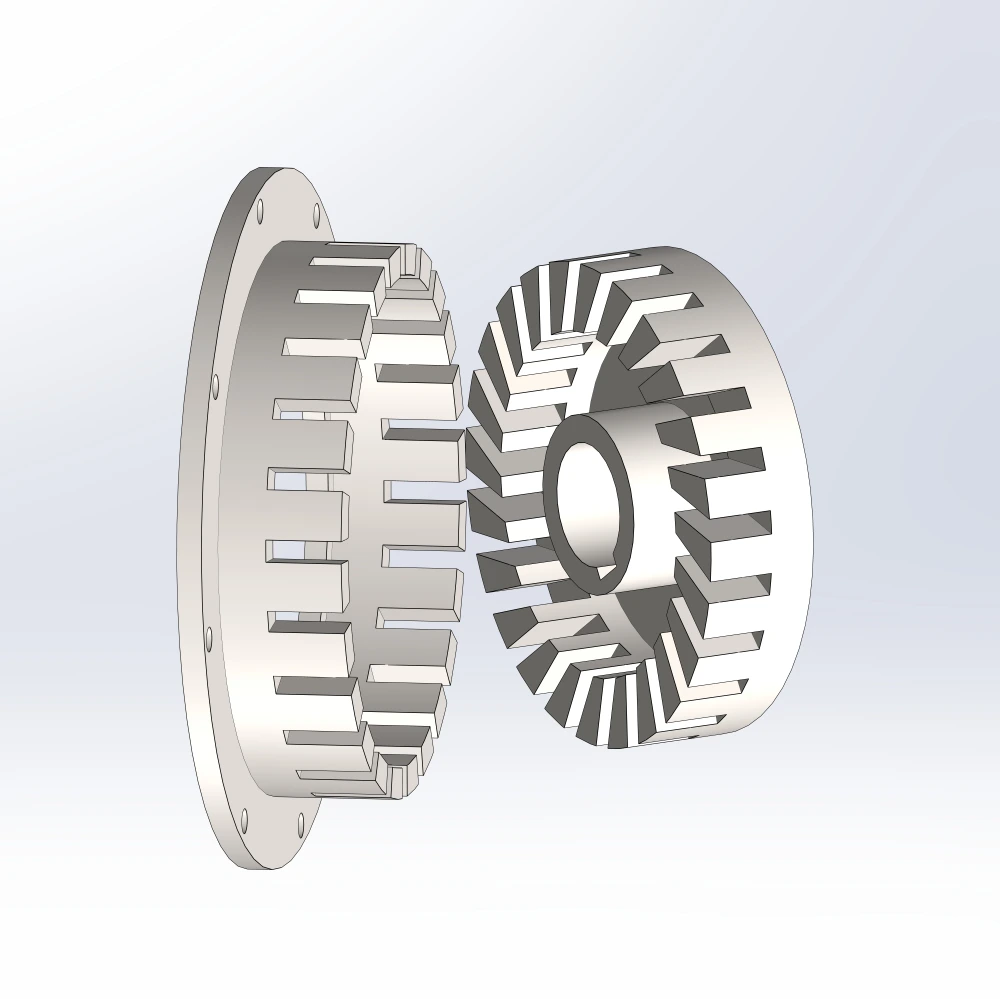

- Precision Particle Size Control: Many dyestuff formulations require controlled particle size to improve solubility and application performance. Our mixing technology delivers high shear and controlled turbulence, allowing for efficient particle size reduction and ensuring better dye penetration and stability.

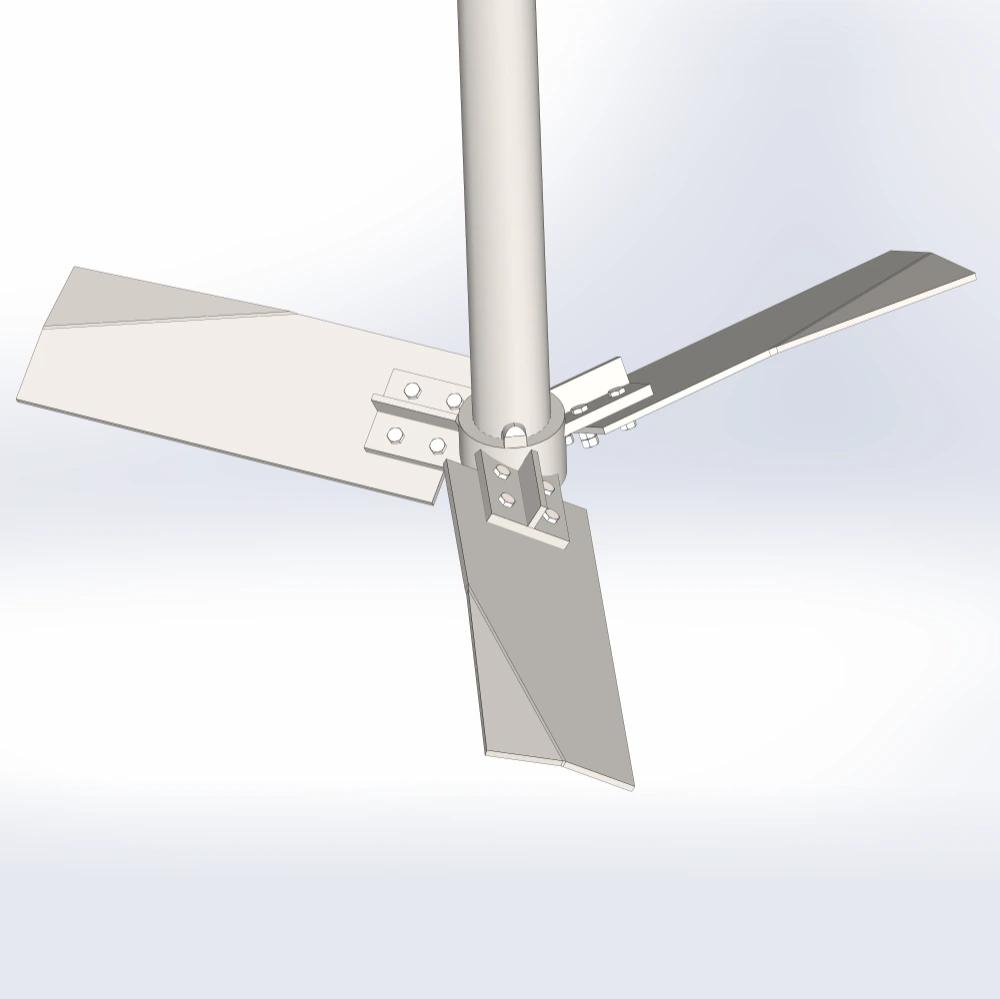

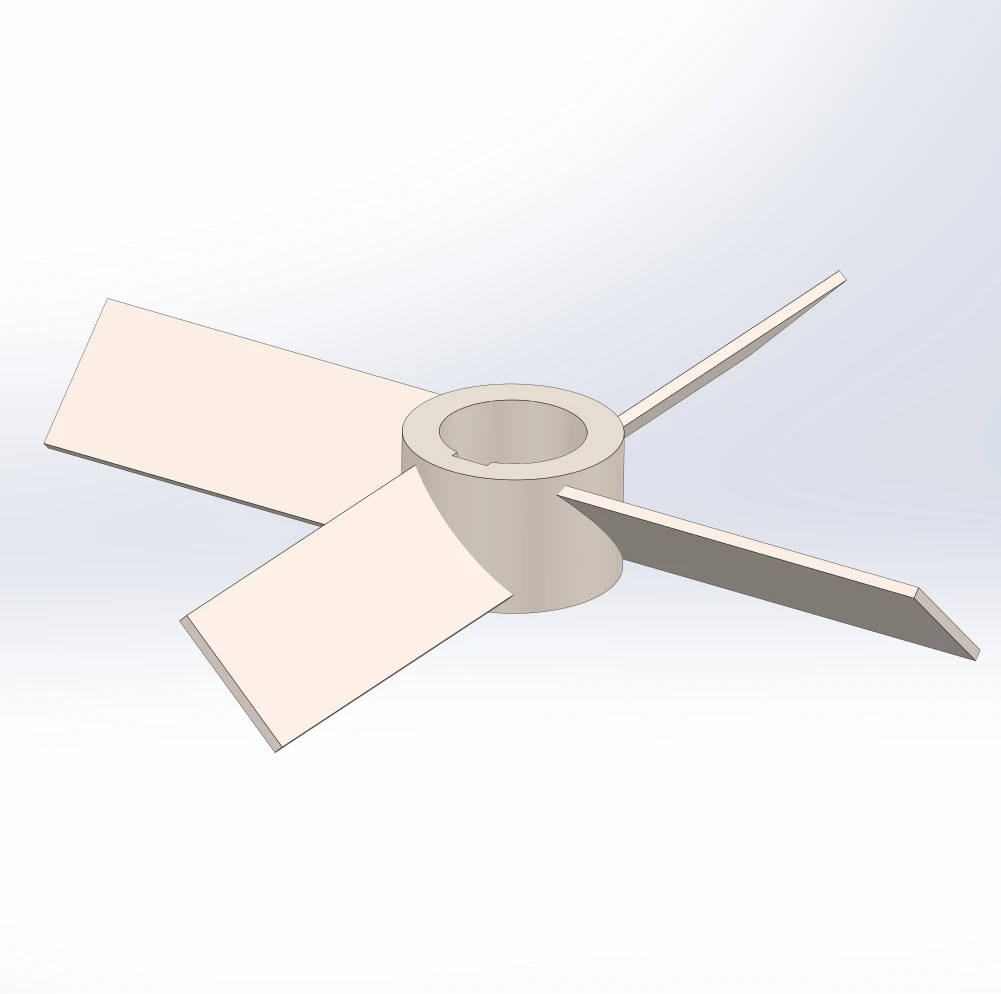

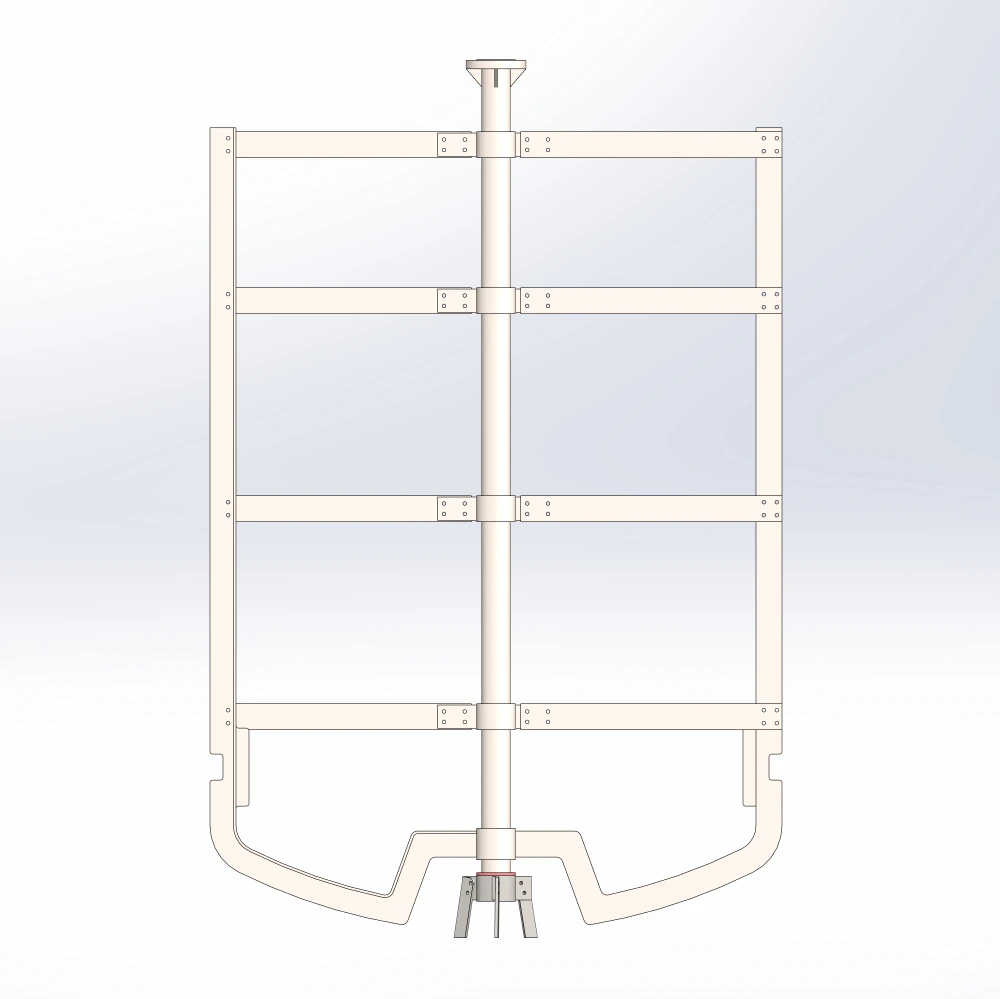

- Optimized Mixing Time and Efficiency: Traditional mixing methods can lead to longer processing times and increased energy consumption. FEDA Inc.'s agitators utilize advanced impeller designs that accelerate the mixing process while minimizing power usage, improving overall efficiency without compromising quality.

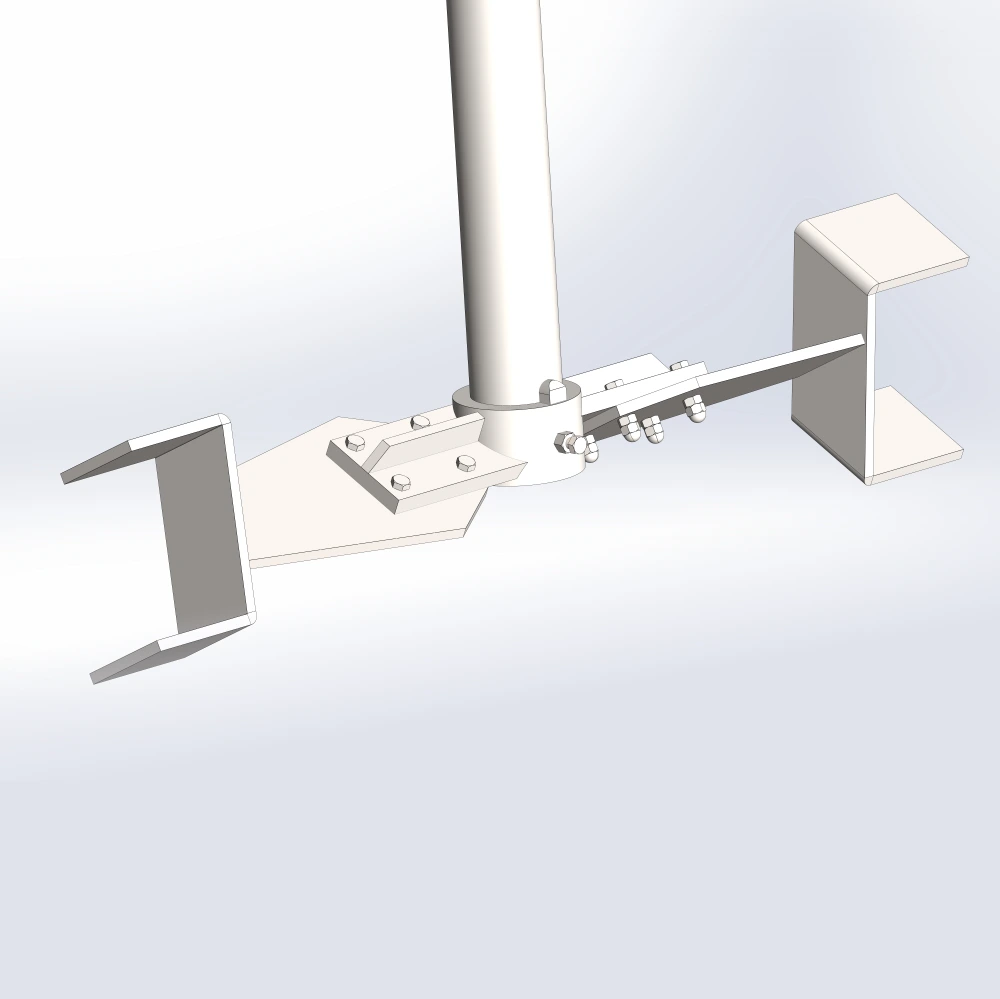

- Process Stability and Reproducibility: Variability in the mixing process can result in product defects and rework. Our agitators provide consistent flow patterns and stable agitation speeds, ensuring reproducibility across batches and reducing the risk of quality deviations.

- Handling Aggressive Chemicals:Dyestuff production often involves corrosive substances. Our agitators are built with corrosion-resistant materials, ensuring durability and long-term operational reliability in demanding chemical environments.